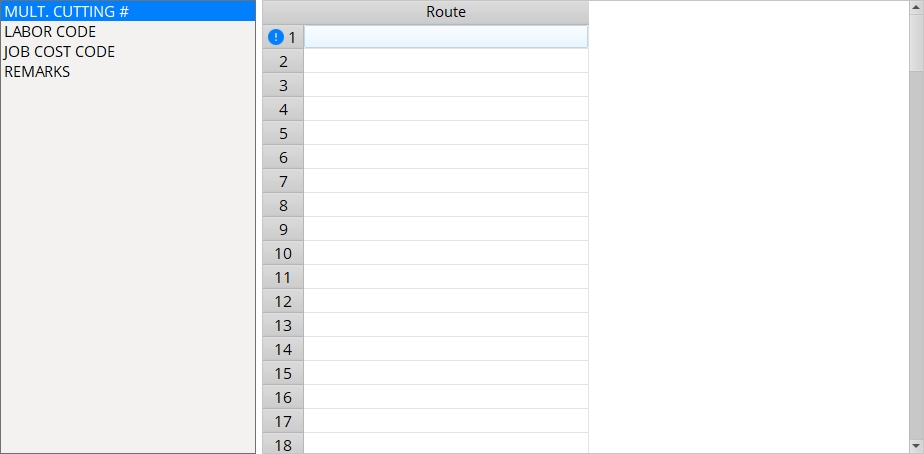

User Routing Settings

Sets the available routing definitions that can be selected in Member Status or Material General Information.

- General Overview

- Tips and Tricks

- Related Tools

|

|

OK (or the Enter key) closes this screen and applies the settings.

Cancel (or the Esc key) closes this screen without saving any changes.

Reset undoes all changes made to this screen since you first opened it. The screen remains open.

- Text entry widgets (moving from cell to cell and within cells)

- Member Status Review (to apply definitions to members)

- Status Update (to apply definitions to member/ material groups)

- Member status > Member route... ( Status Display )

- Material status > Material route... ( Status Display )

- Mult. Cutting # (BOM field that configuration #1 goes into)

- Labor Code (BOM field that configuration #2 goes into)

- Job Cost Code (BOM field that configuration #3 goes into)

- Remarks (BOM field that configuration #4 goes into)

- Member status > Member route '. . '. ( Status Display )

- Advance Bill of Material (may be organized by routing config)

- Sheet Loading Report (may be organized by routing config)

- Status Report by Category (may be organized by routing config)

- Category Settings (alternative to routing definitions)

- Ctrl key (hold down to "tear off" a tab)